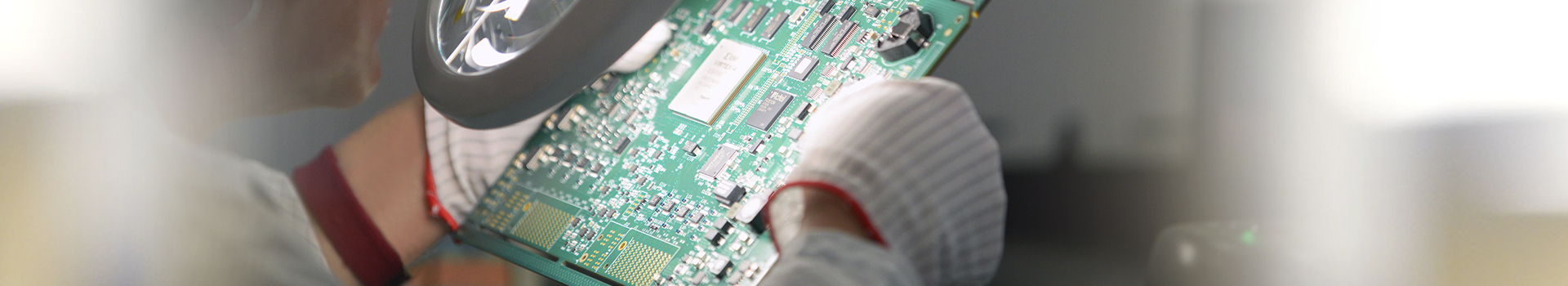

Printed Circuit Board Assembly (PCBA)

A high-yielding PCBA process eliminates latent manufacturing induced defects that can result in field failures and reliability issues. Paramit’s PCBA processes are based on a zero-defect culture, using systems designed to provide a no-defect yield. We use industry leading verification equipment to control critical processes and ensure defects don’t travel down the line.

PCBA Process Validation

Paramit performs process validation on every PCBA we build, whether it’s a standalone product or part of a complex system we manufacture. We thoroughly document the validation process and maintain records that are available to both clients and the FDA.

Best-in-Class PCBAs

Our rigorous methods and technical staff contribute to Paramit’s best-in-class PCBA operation which results in less than 10 defects per million opportunities (DPMO).

- New Product Introduction (NPI). Our NPI process includes a Design for Manufacturability (DFM) review to ensure PCBAs are designed for optimum yield before they move into a production environment.

- Stop-on-defect policy and closed-loop work cells. These strategies prevent products with failures from moving down the line until the cause of defect is resolved.

- Inline inspection. We inspect 100% of the PCBAs we build for solder deposition with a 3D volumetric solder paste system and a post-reflow automated optical inspection. During NPI, we also perform a Design of Experiment (DOE) to design the optimum stencil for screen printing and to determine the solder-paste screen printer settings for ideal solder deposition.

- Offline inspection. We verify 100% of the PCBAs we build for BGA (ball grid array) solder joints using an automated x-ray (5DX) inspection system. This inspection lets us evaluate the integrity of any hidden solder joints, increasing the opportunities for long term reliability.

- In-Circuit Testing (ICT). ICT verifies the electrical integrity of every PCBA using high-end, custom solutions developed by our experienced Test Engineering group.

- Functional test. Our manufacturing engineers have product development backgrounds and experience in test development, troubleshooting, and root cause analysis.

Conformal Coating

Paramit offers in-house conformal coating with dedicated lines for Parylene (C and F) and Silicon chemistries and plasma surface treatment for high wettability. Our new 5,000 sq. ft. operation includes a Nordson ASYMTEK panorama conformal coating line.